Hollow Shaft Motors

Powerful Performance with Enduring Functionality

Hollow Shaft Motors

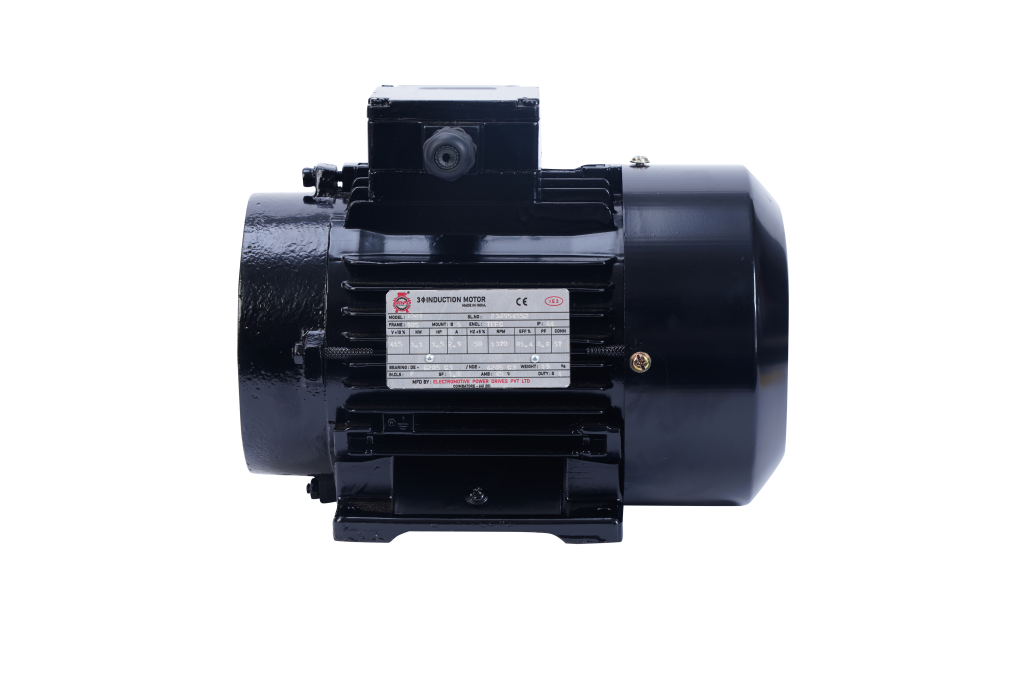

In Hollow shaft pump motors, the pump head-shaft extends through the motor shaft and is joined at the motor’s crest. An adjusting nut is located on the peak of the head-shaft which streamlines the regulation of the pump impeller strength. The primary advantage of the Hollow shaft’s characteristic construction is the enormous weight saving that it brings about, which is advantageous not just from an engineering but also from a functional point of view. In India Hollow shaft Motor are widely Use in Pump, Gear Box, Chemical industries, Textile ect.

Product Specifications

Motor type

Hollow Shaft Motors

Frame Size

63 to 160L

Power

0.18 to 15 kW

Polarity

2, 4, 6 & 8

Mounting

B3, B5, B14 & combinations

Voltage

415V ±10% or as required

Frequency

50Hz ±5% or as required

Protection

IP55 or superior on request

Ambient

40ºC

Construction

Full Aluminium or Alu body with CI enclosure or Full cast iron

Enclosure

TEFC

Ins Class

Class F/ Class H insulation with temp rise limited to class B/Class F

Hollow Shaft Motors

A Hallow Shaft Motor is a special type of electric motor where the shaft is hollow in the center. This design allows the driven equipment, like a pump shaft, to pass through the motor shaft. It offers a compact and space-saving solution for various industrial applications In Tamil Nadu. At Coimbatore EMP Drives, we are proud to be a leading manufacturer and supplier of high-quality Hallow Shaft Motors in India. Our motors are known for their strong performance, durability, and energy efficiency. Whether you need a motor for a pump, gearbox, or textile machine, EMP has the right Hallow Motor for your needs.

Why Choose EMP Hallow Shaft Motor?

EMP Drives offers a wide range of Hallow Shaft Motors designed to deliver top performance in demanding conditions. Our motors are built using advanced technology, ensuring long life, low maintenance, and smooth operation.

Where is Hallow Shaft Motor Used?

Our Hallow Motors are widely used in various industries that require smooth and accurate motion control. Here are some common applications:

Vertical Pumps

Perfect for water treatment plants, agriculture, and irrigation.

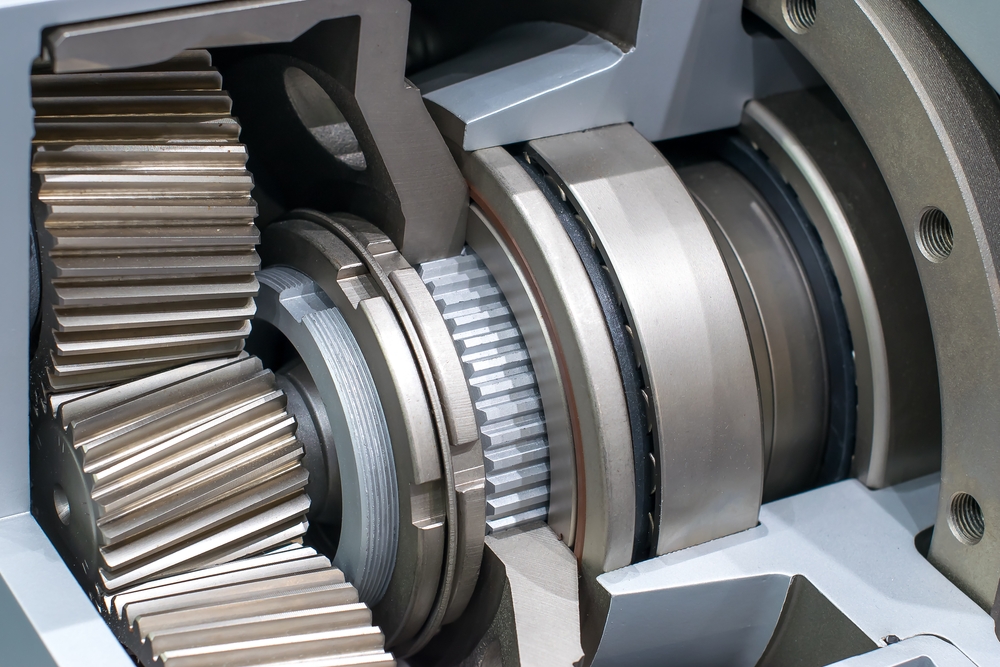

Gearboxes

Used in material handling systems for precise power transmission in Coimbatore.

Textile Machinery

Ensures consistent speed and torque control in spinning and weaving machines.

Chemical Processing

Ideal for pumping solutions in chemical industries.

General Automation Systems

Useful in machines requiring accurate shaft alignment.

Benefits of Using EMP Hallow Shaft Motor

Here’s why industries prefer EMP’s Hallow Motor over traditional solid shaft motors:

Weight Reduction

The hollow design helps in reducing the motor weight.

Compact Size

Takes up less space, which is helpful in machinery with limited room.

Precise Control

Better alignment and smooth transmission of motion.

Longer Lifespan

Designed with robust materials and high-quality insulation.

Low Maintenance

Fewer mechanical parts and easy to install and service.

Customizable

Can be tailored to suit specific industrial requirements.

types of hallow shaft motor

Standard Hallow Shaft Motor

Ideal for pump applications. Designed for direct coupling with vertical pump shafts. Reduces alignment issues and enhances operational efficiency.

Single & Three Phase Hallow Shaft Motor

Suitable for low-power requirements. Best for smaller pump systems and basic machinery. Compact and energy-efficient design. Designed for industrial and high-power applications. Delivers consistent torque and smooth performance.

Custom Hallow Shaft Motor

Built to match specific technical requirements. Options for shaft diameter, frame size, mounting types, and more. Ideal for OEMs and specialized machine setups.

Why EMP Drives?

EMP Drives has been in the motor manufacturing industry for over 35 years. As a company committed to quality, we focus on using the latest technology and best engineering practices. Our team is dedicated to helping customers find the right Hallow Shaft Motor or Hallow Motor for their applications.

- In-house R&D and testing

- Custom-built solutions

- Quick delivery

- Competitive pricing

- Excellent after-sales support